Things change. In this version, the walls are corrected. The arc was wrong on a couple of walls. Just cleaning up the drawing and correcting mistakes that I knew were there. The roof is on. Now I’m playing with the best way to represent wall and roof 1×4 and 1x6s in Revit. Expensive framing add-on to Revit? Manually sticking lumber wherever I need it? Is there something in the Structural menu that I can use? Still fiddling, still learning. Once these are accomplished in a satisfactory way, I can begin working on the actual drawings, with dimensions and such. From there, a bill of materials.

Month: October 2018

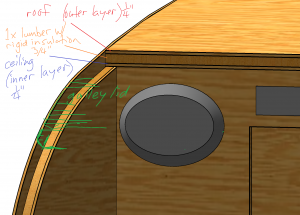

Teardrop 015 roof mass structure

In this design I tried to create, in Revit talk, a mass. It’s a volume of space (3-dimensional) that is not meant to be seen in any drawings but gives the designer a shape to work something else around, like a roof. I failed because of either a shortcoming in Revit or me, one that disallows masses to be extruded sideways (i.e. from one wall to the other).

As it happens, I didn’t really need this. I could have just put a roof on an already existent structure – the walls – and offset the roof line by 1/4″ inch (so, in essence, drawing the ceiling line to make the roof). Why 1/4″? It’s the inner skin of the roof sandwich.

The inner 1/4″ ceiling plywood will be lain perpendicular to the walls, on the 1/4″ inner wall and 1×2 wall structure. This will give it enough roof surface area to firmly attach to the walls. 1×2 spars will follow atop the 1/4″ inner ceiling plywood and give the force necessary to keep the ceiling plywood curved around the walls, starting at the front wall, around the front curve, and over top the actual roof, to terminate at the galley – all colour-coded here for your convenience. Rigid polystyrene insulation will fill up the gaps between spars. (Spars not included in this drawing.)

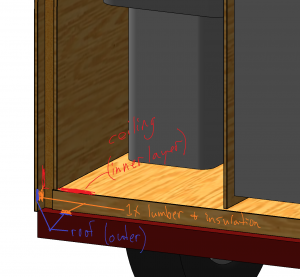

I know what you’re going to say. “There seems to be a gap between the ceiling and the floor, in the second picture.” Yes. I have to fix my walls.

Teardrop 1 016 insulated floor

In this version, the floor is as others have suggested – an insulated floor. Previously I put the insulation panels between the trailer’s frame members. But:

- The steel cross members of the trailer are themselves not insulated and, being steel, will allow a lot of leakage of heat. Even if they were wood, they would still not insulate well.

- Adding insulation blocks under the trailer would not be fun. I really don’t want to crawl around under another camper ever again.

- Sandwiching (screwing & gluing) layers of plywood (top & bottom), lumber (1x2s & 1x4s), and rigid insulation panels would create a much stronger floor. In the corners, where the floor meets the trailer structure, there are bolts holding the trailer together. Drilling out bits of plywood to allow for flush contact will add serious weak points to a single sheet of plywood.

So this version has 3/8″ ply, 1×2 (which is 3/4″ thick), and another 3/8″ ply, totaling 1½”. This would raise the countertop by an extra inch, totaling 32”, a bit too high for my taste (30” max). The solution? Keep the counter at 30” and put in a smaller grey water holding tank (10ℓ).